Tempered steel is among the steels that have a high amount of carbon and allow hardening. These steels, which have managed to come to the fore in many issues such as hardening and surface weight, are used in different areas today.

Another important feature of tempered steel is that it shows toughness in forces such as pulling and pushing. Thanks to this feature, manufacturing is used as steel and is preferred during the production of many parts.

These steels, known as tempering steels and containing carbon, have a great depth of hardness. In this way, tempered steels are used in the production of parts or machines that will be exposed to hard and high forces. On the other hand, tempered steel is manufactured together with various alloys.

What is Reclamation Steel?

There are many curious questions about the steels called breeding. Especially people who use these steels in industrial areas look for answers to many questions. The question of what are tempered steels can also be asked by people who want to use these steels in various fields. This steel, like all other steels, is one of the types of steel used during production in various fields. Steels are produced after mixing each metal and iron with certain components. This allows the production of steel with different values.

One of the steel types produced is tempered steel. Tempered steels are produced by combining various components with different amounts of carbon. These include options such as carbon, chromium element, manganese alloy and chromium-molyb.

All these components are among the factors that increase the ability to harden. For this reason, it is quite possible to produce breeding steels with different hardening and durability capabilities today. In general, reclamation steel models produced with a diameter range of 400 mm can also be manufactured in different specifications.

Reclamation Steel Usage Areas

Due to its properties and components, tempered steels are used in almost every field. The areas of use of reclaimed steel are quite wide. The reason for this is that many parts with hardness and toughness properties are produced in different industrial areas today. It is only possible to gain this feature with tempered steels. Carbonated and other alloyed steels, known as reclamation, are used in many areas. These areas are as follows;

- Various machine parts

- Machine and engine parts

- Forged parts

- Bolt and nut construction

- Crankshaft

- Axle and similar parts

- Connecting rods

Tempered steels are generally used in the construction of the above parts. These steels generally allow stronger parts to be produced and at the same time allow them to have a longer life. In this way, various parts can give higher performance while at the same time becoming more durable.

Reclamation Steel Properties

Thanks to its tempered steel properties, it is one of the most preferred steels today, especially in the field of manufacturing. These steels, which also have various mechanical properties, allow the parts to achieve a high level of hardness. In addition, it is divided into 4 groups within itself. These are as follows;

- Manganese alloyed tempered steels

- Chromium-molybdenum alloyed tempered steels

- Chrome alloyed tempered steels

- Unalloyed tempered steels

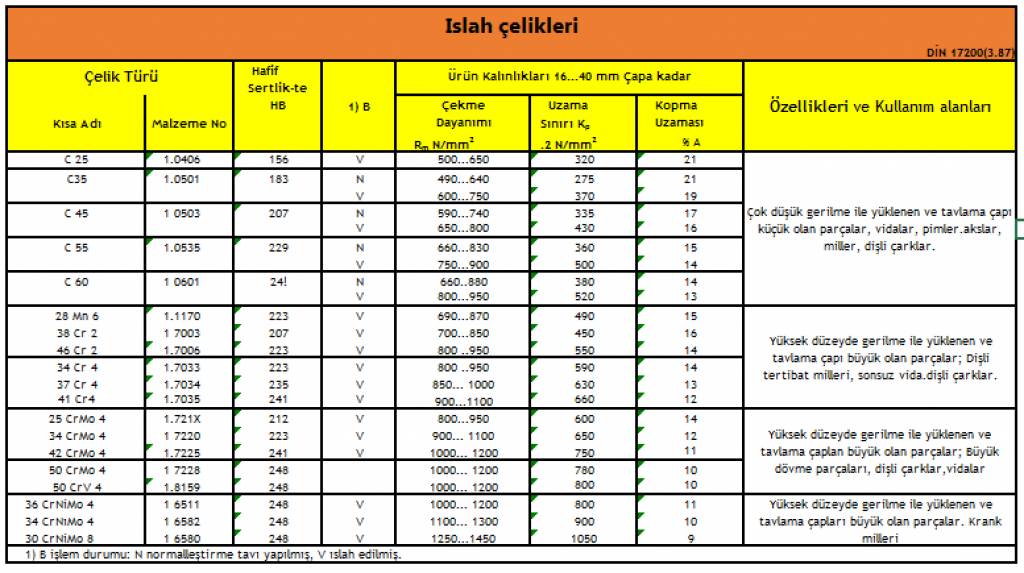

These steels, which are grouped as above, also have different mechanical properties. In general, the lowest yield limit oftempered steel mechanical properties is 370 NM. However, it also has a diameter of 16-40 mm. It also varies according to the amount of carbon within the yield limit.

What are the Most Common Tempered Steel Grades?

Tempered steel can have many different qualities. Generally, different tempering steels are preferred according to the purpose of use, the function of the part and the manufacturing method. However, the most commonly used tempering steel grades are:

42CrMo4: 42CrMo4, also known as high-strength tempered steel, is often used in engine and machine parts. It is also preferred in the manufacture of heavy-duty gears, gearwheels, shafts and similar parts.

34CrNiMo6: 34CrNiMo6 steel exhibits a high performance in terms of strength, toughness and fatigue strength. For this reason, it is used especially in the production of parts working under high stress. Examples include crankshafts, gearwheels, shafts, axles and similar parts.

30CrNiMo8: 30CrNiMo8 steel is known for its high strength and toughness properties. Therefore, it is preferred in the manufacture of heavy-duty parts such as high-temperature engine parts, gearwheels, crankshafts and the like.

18CrNiMo7-6: 18CrNiMo7-6 is a grade of tempering steel with high strength and toughness properties. It is used especially in the production of parts under high load such as bearing bearings, gearwheels, eccentricities and crankshafts.

This is just a few of the most commonly used tempering steel grades. The choice of tempering steel quality may vary depending on factors such as the purpose of use, the function of the part, the conditions under which it will remain under load and the manufacturing method.

What is 42CrMo4 Tempered Steel?

42CrMo4 tempering steel is an alloy steel and is an ideal choice for many industrial applications. This steel stands out thanks to its high strength, high toughness and abrasion resistance. 42CrMo4 tempering steel is an alloy steel containing 0.38-0.45% carbon, 0.6-0.9% manganese, 0.15-0.30% silicon, 0.9-1.2% chromium, 0.15-0.25% molybdenum, and a maximum of 0.035% sulfur and phosphorus.

42CrMo4 Tempered Steel Specifications

42CrMo4 tempering steel is a steel that is easy to form and process at high temperatures. In addition, thanks to its high strength, high toughness and abrasion resistance properties, it is an ideal choice for many industrial applications. Its mechanical properties are also quite impressive. High abrasion resistance, fatigue strength and impact resistance properties make steel an ideal choice for many industrial applications.

42CrMo4 Tempered Steel Usage Areas

42CrMo4 tempering steel is an ideal choice for many industrial applications thanks to its properties such as high strength, toughness and abrasion resistance. For example, it is widely used in industries such as automotive, mining, construction, energy and aerospace. 42CrMo4 tempering steel is also frequently used in machinery and equipment working under heavy loads.

42CrMo4 Tempered Steel Manufacturing Process

42CrMo4 tempering steel is alloyed primarily after crude steel production. It is then shaped by hot rolling. Finally, the desired properties are obtained by applying cold rolling, hot forging or hot working processes. This process, called tempering steel,

by making changes in its molecular structure, it increases properties such as durability, hardness, fatigue strength, wear resistance.

First, during the raw steel production process, carefully selected raw materials are used to produce high-quality steel pulp. These doughs are melted at high temperature and under high pressure. After melting, the steel pulp is gradually cooled and poured.

The bars obtained after casting are shaped in the hot rolling machine. This process is applied to reduce the diameters of the bars, increase their length and shape them homogeneously. During this process, the rods are exposed to high temperatures, resulting in changes in their molecular structure.

The next step is the cold rolling process. This process is applied to further reduce the diameters of the bars obtained after hot rolling. The cold rolling process causes the steel bars to harden and increase their strength

Hot forging or hot working processes are applied for 42CrMo4 tempering steel. These processes allow the steel to be shaped more easily due to the high temperatures. During these processes, further changes occur in the molecular structure of the steel and the desired properties are obtained.

As a result, the production of 42CrMo4 tempering steel involves a number of processes, such as the melting of carefully selected raw materials, hot rolling, cold rolling, hot forging or hot working processes. During these processes, changes occur in the molecular structure of the steel and it is ensured that the steel gains the desired properties.

The prices ofreclaimed steel may also be curious by individuals who want to buy these steels. However, it is not possible to give a clear price in this regard. The reason for this is that the prices of tempered steels vary according to certain factors, as in hardening steels and other varieties. For this reason, it is not possible to give a clear price information.

The prices of reclaimed steel are not the same for every steel. There are many factors that affect the prices of steels. The most important of these factors is the components in steel.

The prices of reclaimed steel are not the same for every steel. There are many factors that affect the prices of steels. The most important of these factors is the components in steel.

Frequently Asked Questions

Tempered steel is a type of steel that has a high amount of carbon and allows hardening. These steels are produced by combining them with various components.

Tempered steels are often used in the manufacturing industry and are preferred in the manufacture of various machine parts, engine parts, forged parts, bolt and nut construction, crankshaft, axle and similar parts.

Tempered steels are used to increase the hardness of parts and ensure their durability. It is one of the most preferred steels in the manufacturing sector thanks to its mechanical properties, hardness and toughness.

Tempered steels are divided into four groups: manganese alloy tempered steels, chromium-molybdenum alloy tempered steels, chromium alloy tempered steels and unalloyed tempered steels.

Prices of tempered steel vary according to factors such as components, alloys and mechanical properties in steel. It is best to contact the seller companies to get a clear price information and get a price in line with the order amount.