Iron is one of the most robust elements and minerals found in nature. However, when iron is used alone, it corrodes over time if it is not exposed to any process. External factors such as natural events, rain, wind react with the elements in the iron, causing phenomena such as rusting and weakening of the iron.

Due to the corrosion of iron after a certain period of time, various researches have been carried out since ancient times. Since it is also used especially in the construction of war tools, it is tried to prevent the corrosion of iron. In this sense, as a result of the studies, first steel was found with the carbon alloy added to the iron, and then chromium was added to the steel to make the steel even stronger and stainless steel was revealed.

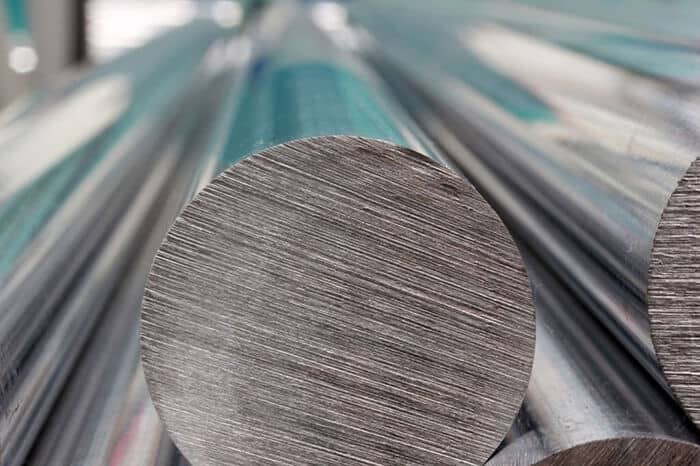

Stainless Steel

The discovery of iron dates back to ancient times. With the discovery of iron and learning how to shape it, its use is increasing in many areas. Iron has been used for a long time, especially in the production of attack and defense vehicles. However, although iron is a solid element, it rusts and loses its strength as a result of its reaction to natural events after a while. For this reason, studies on iron have been carried out since ancient times.

Iron and phosphorus were first mixed in the construction of an iron column made in India in the 4th century. Later, in the 19th century, metallurgical studies accelerated and alloys such as low carbon and high carbon began to be tried. Within the scope of the studies carried out in this context, carbon and steel were obtained at the levels of 0.2-2.5% added to iron.

Steel is much stronger than iron and can be used for a long time. However, it corrodes over time in steel. As a result of the studies conducted to prevent this, chromium was added to the steel and a stronger and rust-resistant stainless steel was found. In this way, items such as knives and pots that we use in this can be produced. As spectral metal, we have been continuing our services in the production of steel and stainless steel for more than 10 years.

What is Stainless Steel?

Among the people, the concepts of iron, steel and stainless steel are used by mixing them together and a big mistake occurs. So, what is stainless steel? For stainless steel, first of all, it is necessary to create the steel by processing the raw iron and adding a certain amount of carbon. Stainless steel, on the other hand, is a very strong metal that is formed by adding chromium to the steel.

Steel is formed by adding carbon to iron. The reaction that occurs when the chromium added to the steel combines with oxygen is called chromium-oxide. With this reaction, a thin layer is formed on the steel. In this layer, it gives stainless property to steel. Only chromium is not added to obtain it from steel for stainless steel. As a result of mixing many different elements into steel, stainless steels with different properties and strength can be obtained.

Different types of stainless steel are formed as a result of different mixtures to be made into steel. Thanks to these added mixtures, stainless steel with different hardness and durability can be obtained. Stainless steel is used in many different areas, especially in the arms and defense industry.

Features of Stainless Steel

It is used in many different areas because it is resistant to corrosion. The most used areas are the products that have direct excessive contact with water and temperature. In this regard, it is directly used in many different areas such as kitchen utensils, car spare parts, defense industry and white goods.

When the stainless steel properties are examined, it is seen that the anti-corrosion resistance is increased thanks to the different alloys added to the steel. As spectral metal, we have been serving in the sector for many years in the field of steel and stainless steel with a fast, durable and affordable price policy.

Main Features of Stainless Steel;

It is highly resistant to corrosion (rust).

Thanks to the nickel used in the mixture, it does not leave water stains on it.

It is heat-resistant. There are species that withstand up to 1200 degrees.

It has the ability to be easily processed and shaped.

It has a very stylish appearance aesthetically and decoratively.

It is very easy to add to each other by using resources.

Some types of stainless steels do not have flooding even at high temperatures. In this way, its mechanical strength continues. Likewise, some species do not have embrittlement at low temperatures and maintain their toughness.

It is hygienic thanks to its easy cleaning and smooth structure.

Since stainless steel is quite durable, it is long-lasting and economical.

Stainless Steel Price

Stainless steel is obtained by mixing different elements to the steel metal. In general, stainless steel is made by adding chromium to the steel. However, different types of stainless steel are produced by adding different alloys in the production of stainless steel. Different types of stainless steels are obtained according to the area where the steel will be used.

Different types of stainless steel are used depending on the area where the material will be used. For this reason, stainless steel prices vary according to their characteristics and types. As spectral metal, our primary goal since the day we were first established is to offer affordable and quality steels to all over Turkey. In this regard, attention is also paid to this policy in the production and use of stainless steel.

Çelik ve paslanmaz çelik konusunda her türlü ihtiyacınız için bizlere spektralmetal.com.tr adresinden ulaşım sağlayabilirsiniz.

Mines Used in Stainless Steel Production

Iron is one of the most robust and widely used mines in nature. Thanks to the carbon added to the iron, more robust products are obtained. However, the most used mineral in the world is actually stainless steel, which is the mixture of two elements. So what are the types of minerals used in stainless steel production?

The field of use of stainless steel is so wide. Different types are obtained with different mixtures according to their use in different areas. The main components of stainless steel consist of iron, chromium, carbon, nickel, molybdenum and a small amount of other metals.

Chromium and Nickel Mixture: The most important substance in the formation of stainless steel is undoubtedly chromium. Chrome forms a layer against rust and ensures that the steel is durable. Nickel helps stainless steel to be more stable. Thanks to nickel, it reduces the cracking threshold that will occur as a result of the stress of the steel used in the manufacturing industry.

Manganese: It increases the resistance of the material during production and in doing so, it interacts with the sulfur in the steel. Strength is also increased by substituting manganese with nickel and then combining it with nitrogen

Molybdenum: Removes corrosion resistance on large covers. It also greatly prevents formations such as cracks and pits.

Since different types of stainless steel are needed according to their areas of use, mixing is done with different mines to adjust their hardness and condition.

Types of Stainless Steel

Stainless steel has different types and qualities according to its areas of use. These types and the quality of stainless steel vary according to the material used. One of the distinguishers here is conductivity, shaping and mixing. The most used type today is 304 quality stainless steel.

304 quality stainless steel was developed by William Herbert Hatfield at Firht-Vickers in 1924. It forms the basis of stainless steel and is the most used type in many areas.

Since 304 stainless steel contains between 20% chromium and 2% nickel, its conductivity is low. It is noteworthy that this type of cola, which is in the estentic stainless group, is shaped and easier to find on the market. Price is one of the most preferred types because it is more efficient in terms of performance.

AISI 304 Quality Stainless Steel

Stainless steels are named with different quality types. It is more functional than other types in terms of the most preferred 304 stainless steel properties. It differs from other types in its corrosion resistance, heat resistance, mechanical properties, weldability, machinability and malleability.

It is much more resistant to corrosion against other types of steel. Since it has a structure resistant to different types of chemical dyes, it is frequently used in daily use. It is also resistant to different pressures to be used in sectors depending on use. It is not recommended because it may rust in abnormal corrosive environments.

Since 304 quality stainless steel is produced mostly according to daily use, it can withstand temperatures of 425 to 860 degrees. It is not recommended because it is not resistant to carbide deposits. It has a mechanical feature suitable for daily use. Not suitable for use in environments where a high rate of leakage or rupture may occur.

304 quality stainless steel is a type of steel adjusted to daily use. For this reason, it is not suitable for annealing at temperatures exceeding 1000 degrees. For this reason, it should be forged by cold rolling instead of annealing.

Other Types of Stainless Steel

Stainless steel is used for many different reasons both in daily use and in the industrial area. Especially stainless steels in daily use are less durable than other steels. Stainless steels are obtained with different metals added to the steel. Each has different stamina. The most used type of steel is 304 stainless steels.

316l stainless steel contains lower carbon than 304 stainless steel. It is obtained by adding more nickel and malibden to 304 quality stainless steel. It is preferred because it is more durable than 304 quality steel with certain properties.

316l stainless steel properties and uses;

316l stainless steel is a type of steel that includes low carbon.

In addition to the standard properties of stainless steel, intergranular corrosion resistance is excellent.

316l stainless steel is not corroded, especially because it contains low carbon at high temperature in the parts to be welded. It also offers time and price savings as it does not require annealing.

316l stainless steel is a type of steel with higher rupture resistance.

It is preferred to be used in equipment used in sea water and equipment used in high chemical. It is also widely used in paper, paint, acetic acid, fertilizer, photography and food industry, seaside, constructions, ropes, bars, bolts and nuts.

What is Forged Steel?

It was obtained by adding 2% carbon to the steel iron mine. Studies show that steel and iron were used until 4000 years ago. Since steel is a hard element, it is real in some processes, especially in shaping. This processing and shaping is called steel forging.

When we look at the areas of use offorged steel, it is seen that it is used in many things that we touch. The steel forging process is generally divided into areas such as hot forging, semi-hot forging and cold forging. Hot forging is a process of shaping an important steel used throughout history. It was generally used in the construction of tools such as swords and knives.

Materials such as bolts, rivets, bars, turbine shafts, coins, medals, gears, hand tools, aircraft parts, automobile spare parts are mostly produced using the forged steel method. The forging process can be done by heating the steel or in the form of cold forging using special materials.

As Spektral Metal, we provide high quality services with the highest equipment in both hot forging and cold forging. We are just a click away from you whenever you need.