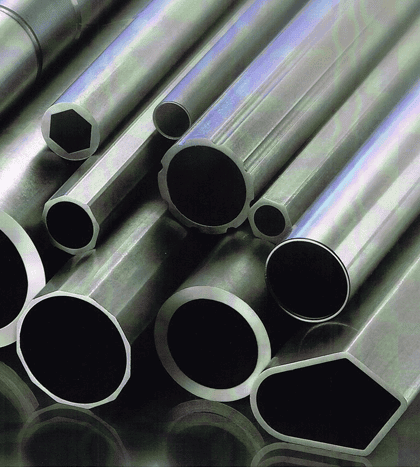

Pipes are generally preferred in industrial areas in accordance with DIN 2394, TS EN 10305-3, TS EN 10219-2 norms.There are different types of manufacturing and measurement according to the material type and manufacturing methods of thepipes . As we said, pipes add a wide range of products. There are differences in themselves such as hollow, filled, natural gas pipe, stainless type, shiny surface according to their types. Pipe types with a stainless structure have a decorative look with their glossy surfaces. The weights and dimensions of the pipes can also be determined individually. Product volumes produced with substances that can be determined according to the dimensions and weights herein can be found.

It is extremely important that the pipes in the areas where the pressure value is high are cut correctly without any professional errors. Steel pipes with steel tubes are more resistant to high pressure. The pipes, which can be cast in one piece, are poured into different molds while they are hot and take their round form. Then, after the pipe cutting process, the cooling process is carried out and the stains that may remain on the steel pipes of the cylinder machines are removed. After the parts of the pipes obtained as a result of the process are taken from the machine, the cutting dimensions are checked for the last time. At the end of the procedures, all necessary maintenance and cleaning procedures are started to be applied. You can examine our pipe types and products below.

- ST 28

- ST 34-2

- ST 37-2

- ST 44-2

- ST 52-3

Three methods are used in metal pipe manufacturing.

- Seamless : Tensile

- Tensile Stitched : Welding

- Welding Casting : Casting

Materials used in Pipe Manufacturingare generally black or galvanized steel, iron, copper, aluminum products.

SOME DEFINITIONS USED IN PIPES |

||

| Old Definition | New Definition | Description |

| + BK | + C | Not heat treated after cold drawing (hard gloss) |

| + NBK | + N | Normalized under protective gas after cold drawing |

| + GBK | + A | Annealed under gas after cold drawing |

| + BKM | + CR 1 | Not normally heat treated,but suitable for final annealing |

| + CR 2 | Not heat treated after welding and measurement calibration | |

| + BKW | + LC | After heat treatment, it has undergone a complementary cold drawing process with very little deformation (soft) |