We can say that the question of what is chamfering in machinery is called the softening of the corners that are hard by rounding. The softened version of a 90-degree corner by cutting the ear is called 45-degree trimming. This does not necessarily have to be 90 degrees, if the corner is 120 degrees, the chamfer becomes a 60-degree chamfer. For example, the vertical edges of the glass are chamfered in the glass wall partitions. It is exactly the case of angling a pointed corner. By definition, the chamfer command in AutoCAD can also be used to merge two perpendicular edges more smoothly.

What is the Purpose of Chamfers

The most common reason to create chamfering on the edges is to make sure that the edges are not sharp. As a result of the processing processes, sharp edges that can cut the finger or meat may remain on the edges of the part. Even if there is no very sharp edge left behind in the processing process, there may still be residual burrs in this area. In addition to removingchamfering burrs, it also eliminates the need for other deburring methods.

The presence of sharp edges and burrs in the finished parts is generally unacceptable. Chamfer burs are one of the important tools used in deburring processes. If all the edges need to be broken, the edges can be chamfered with a chamfer cutter. Another area of use of chamfer mills is to ensure that the bolt heads are flat by placing them in a recess on the surface. Chamfering also gives good aesthetic results. It makes the edge less sensitive to damage and deforming effects. In cases where two parts need to be welded together, machining of both parts with a chamfer along the edges of the joint to be welded will support the process.

Chamfering Tools Chamfering Mills Cutters and Milling Bits

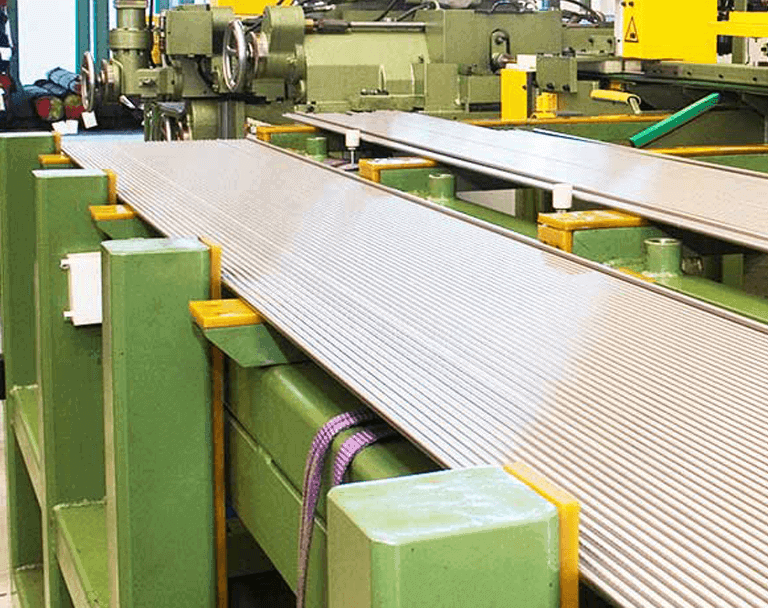

If you are looking for tools, inserts and cutters used for chamfering in online stores, you can find them in different names such as chamfering tools, chamfering tools, chamfer mills, chamfer cutters, chamfer cutters, chamfer inserts or chamfer milling inserts. Since they are all a type of end mill, it is possible to call them chamfer mills in general. Typically, the appearance of the chamfer mills is as follows;

Chamfering Mills May Have Multiple Uses

In addition to forming chamfer, which is the main function of a chamfer, it is preferred in multiple machining operations, including beveling, anchoring, countersinking, engraving and centering. Taking advantage of this team in more than one area of use helps to reduce team changes and save time.

Chamfered Holes and Tailstock Drills for Chamfering

Most holes, especially threaded holes, are chamfered to remove burrs. In addition, chamfering is also done to create a clean start for the teeth. A tailstock drill can also be used instead of a conventional chamfer mill for this operation. In this way, both the hole is marked and the chamfering process is carried out using the same tool.

Chamfer Depth Calculator

The G-Wizard feed and speed calculator also provides convenience in determining the chamfer depth and has a special geometry calculator. The same calculator also has the database that needs to be opened for fasteners. It also has a useful database that calculates the size of the basin.

Chamfering Tool Used in Deburring Process

The chamfer cutter can give great results for deburring. There are many different ways of deburring, but a chamfer mill is one of the most efficient because it can automate the process. Manual deburring takes a long time. This is one of the main factors that popularize the use of deburring tools in CNC machines. When used in deburring, all edges of the chamfering tool are involved in the process.

| Section | Interval | Angle | Length |

|---|---|---|---|

| Rounded | 5,000 ÷ 6,500 | 45° / 30° | 3000 ÷ 4000 |

| Rounded | 7,000 ÷ 75,000 | 45° / 30° | 3000 ÷ 6000 |

| Hexagon | 6,000 ÷ 11,000 | 45° / 30° | 3000 ÷ 4000 |

| Hexagon | 12,000 ÷ 65,000 | 45° / 30° | 3000 ÷ 6000 |

| Square | 6,000 ÷ 11,000 | 45° / 30° | 3000 ÷ 4000 |

| Square | 12,000 ÷ 40,000 | 45° / 30° | 3000 ÷ 6000 |