Cementation steels are generally one of the steels that must have a hard surface and are used in products resistant to impacts and strains. This steel has a high level of durability compared to all other steels. For this reason, it is especially preferred for the surfaces to be processed today.

However, hardening steels are mostly used after the parts become the final surface. For this reason, it provides an easier processing opportunity. It has values of 0.10 to 0.20 as the preferred %C rate of hardening steel for producing impact resistant parts.

In addition, these values also express the carbon value in steel. Thanks to these distinctions, the areas where steels will be used are expressed. Each area has its own characteristics. In this way, it is aimed to get maximum benefit from the steel and the part to be produced by using steel. These steels, like all other types of steel, are obtained by combining various components and alloys.

What are Cementation Steels?

Cementation steel since is used in different areas in daily life, there are many curious issues about this steel. for individuals who constantly need steel It is quite possible for individuals who constantly need steel, especially in industrial areas , to encounter steels called cementation and to ask the question of what is cementation steel.

What are hardening steelsThe most accurate answer to the question of is metals with a high carbon ratio and at the same time, they are alloyed with various components and used to maximize the surface hardness and durability.

Cementation steels These metals, called are now used in a variety of fields. At this stage, how much carbon the metal contains and the other components in it are important as a priority.

The reason for this is that the carbon ratio and other alloys change the durability value of the hardening steels. In addition, these steels can sometimes be produced without carbon or other alloys. Both alloyed and non-alloyed hardening steel are especially preferred for the manufacturing field.

Cementation Steels Usage Areas

Cementation steels have a wide range of uses. In general, the areas of use of these steels are determined according to the stages of cementation. In general, the areas of use of hardening steels are as follows;

- It is used in construction and machine parts with moderate strain.

- It is preferred in various machine parts such as rollers, measuring tools and gears.

- It is preferred in vibratory machines.

- It is used in parts suitable for forcing such as gear wheels, sprockets and shafts in automobiles.

- It is preferred in power and force transmission parts.

- It is used in roller bearings and various rollers.

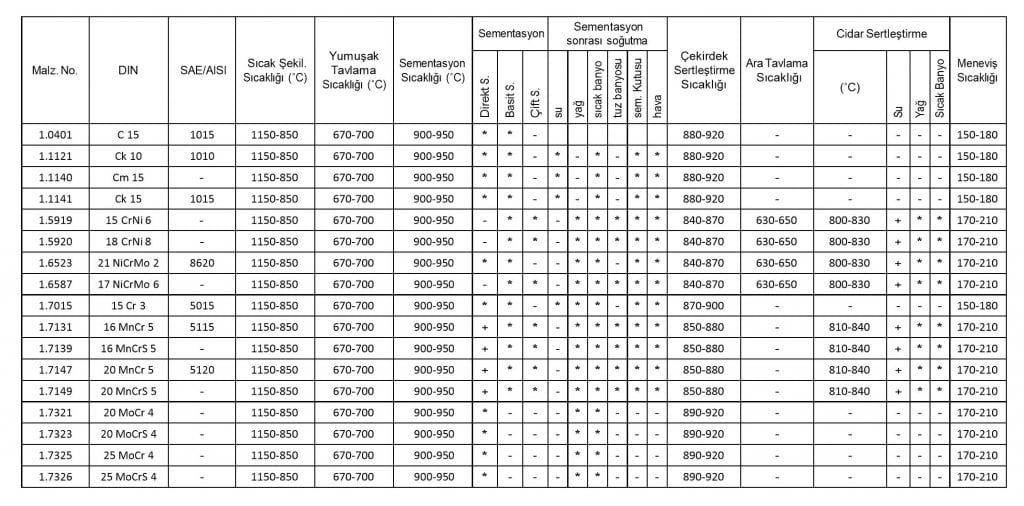

Cementation areas of use of steels However, at this stage, the chemical components DIN and SEA values of the steel are important in determining which area to use.

Cementation Steel Properties

Cementation steelshardening steelsare used in many parts, especially in industrial and various manufacturing areas. The most important feature of these steels is their durability

The properties of the steels may also vary according to the components in them. For this reason, individuals who want to achieve a clear mechanical property should primarily master the components and alloys in steel. For example, carbon or other alloys in cementation can greatly change mechanical properties.

In addition to their durability, their welding capabilities are quite high. In this way, it can allow a great deal of core hardening. This is important for sufficiently hardening the desired area.

Properties of cementation steels one of the most important is the amount of carbon. The amount of carbon in this steel is slightly higher than others. This allows the desired slope, hardness and transmission force to be obtained.

What are the Most Common Cementation Steel Grades?

Cementation steel is an ideal material for surface hardening. This type of steel has a suitable structure for surface hardening due to its high carbon content. Cementation steel is produced in different qualities according to its field of use. Here is detailed information on the most commonly used cementation steel grades:

1. 16MnCr5: This grade is widely used due to its high strength and wear resistance. It is among the low-alloy steels and the surface hardness after the hardening process can reach up to 60 HRC. Uses of this quality include gears, shafts and bearings.

2. 20MnCr5: This grade has a higher carbon content than 16MnCr5. Therefore, a higher surface hardness is obtained after the hardening process. The surface hardness can reach up to 62-63 HRC. Uses of this quality include gears, shafts, bearings and other parts working under heavy loads.

3. 8620: This grade is a cementation steel with a relatively high nickel content. Therefore, it provides a higher impact strength and surface hardness. The surface hardness can reach up to 60-62 HRC. Uses of this quality include gears, shafts, bearings and other parts working under heavy loads.

4. 4320: This grade is a cementation steel with a high chromium content. Therefore, it provides a higher surface hardness and wear resistance. The surface hardness can reach up to 58-60 HRC. Uses of this quality include gears, shafts, bearings and other parts working under heavy loads.

5. 9310: This grade is a cementation steel with a high nickel and chromium content. Therefore, it provides a higher surface hardness and wear resistance. The surface hardness can reach up to 62-63 HRC. Uses of this quality include gears, shafts, bearings and other parts working under heavy loads.

As a result, cementation steel is an ideal material for surface hardening. Its most commonly used grades include 16MnCr5, 20MnCr5, 8620, 4320 and 9310. Each quality has different areas of use and features. Therefore, choosing the correct quality is important for the performance and durability of the part.

What is 16MnCr5 Hardening Steel?

16MnCr5 hardening steel is a type of low-carbon steel. It is hardened by adding a hardening material to its surface. This steel has high strength, hardness and abrasion resistance properties. Thanks to these properties, it is used in many applications.

What are the Features of 16MnCr5 Hardening Steel?

16MnCr5 hardening steel attracts attention with its high strength, hardness and abrasion resistance properties. In addition, it has high durability, good fatigue life, low temperature strength and machinability properties. Thanks to these properties, 16MnCr5 hardening steel is widely used in many industries.

What are the Areas of Use of 16MnCr5 Cementation Steel?

16MnCr5 hardening steel is widely used in the production of gear wheels, shafts, pinions, crankshafts, bearing bearings and other parts that require strength. It is also used in the automotive industry, hydraulic systems, agricultural machinery and machinery manufacturing.

How is 16MnCr5 Hardening Steel Processed?

16MnCr5 hardening steel is a material that requires careful control of parameters such as temperature and cooling speed. Attention should be paid to temperature control to maintain hardness, durability and other properties during processing. Cutting speed and feed rate are also important during machining. In addition, it requires a hardening process after the steel is processed.

Why Is 16MnCr5 Cementation Steel Preferred?

16MnCr5 hardening steel attracts attention with its high strength, hardness and abrasion resistance properties. In addition, it has machinability properties. Thanks to these properties, it is preferred in many applications. In addition, its cost is lower than other high-strength steels, which is an advantage. In addition, thanks to its high strength, 16MnCr5 hardening steel can also be used in the production of thin parts. Steel can maintain its strength even when used at high temperatures, which is one of the reasons why it is preferred in many applications.iliklere göre daha düşüktür, bu da bir avantajdır. Ayrıca, yüksek mukavemeti sayesinde 16MnCr5 sementasyon çeliği, ince parçaların üretiminde de kullanılabilir. Çelik, yüksek sıcaklıkta kullanıldığında bile mukavemetini koruyabilir, bu da birçok uygulama alanında tercih edilmesinin nedenlerinden biridir.

How is 16MnCr5 Cementation Steel Quality Control Performed?

16MnCr5 hardening steel manufacturers pay attention to the quality control process. Steel is tested by methods such as hardness test, traction test and metallography test. These tests help determine the quality of the steel. In addition, the chemical composition of the steel is also strictly controlled.

How is 16MnCr5 Cementation Steel Stability Achieved?

16MnCr5 hardening steel is a material that requires careful control of parameters such as temperature and cooling speed. It is also important that the steel is processed and hardened correctly during machining. When the right processing techniques are not used, the quality of the steel may decrease and undesirable results may occur. As a result, 16MnCr5 hardening steel attracts attention with its high strength, hardness and abrasion resistance properties. This type of steel, which can maintain its strength even at high temperature, is used in many applications. However, if it is not processed correctly or quality control is not carried out, the quality of the steel may decrease and undesirable results may occur.

Cementation Steel Prices

Cementation steel prices are generally determined according to many factors. This is because this steel is produced in different properties and different types. For this reason, prices are shaped according to many factors. The factors that are considered when determining the prices of cementation steels are as follows;

- The amount of carbon in the hardening steel,

- Dimensions of steel,

- Type of cementation steel,

- The number of steel to be purchased,

- Other components and alloys found in hardening steels,

As in tempered steel and other steels, the above factors determine the prices of hardening steel. However, in order to obtain clear price information, it is necessary to contact the companies and institutions that sell hardening steel. In this way, it is possible to reach clear prices and get the most accurate information about the product features.

Frequently Asked Questions?

Cementation steel is a heat treatment method used to increase carbon density on the surface of a steel with low carbon content. This method increases the carbon depth on the surface of the steel and allows it to be hardened.

Cementation steel is used in applications that require surface hardness. This type of steel offers a surface hardness that provides high wear resistance and at the same time maintains the strength properties of the steel's interior.

Cementation steel is used in the production of parts that require high surface hardness and strength properties such as gears, pinions, bearings, cylinders, molds, injection molds, shafts and shafts, screws, nuts.

To produce hardening steel, the steel is first heated and then slowly cooled in a carbon-rich environment. This process causes the carbon to condense on the surface of the steel, forming a hardening layer.

Cementation steel is different from normal steel in terms of surface hardness. While normal steel has a homogeneous structure, a carbonaceous layer is formed on the cementation steel surface. This layer provides high hardness and abrasion resistance.

Sementasyon çeliği, yüksek sertlik ve aşınma direnci nedeniyle işlenmesi zor olabilir. İşleme öncesi çeliğin sert yüzeyi öncelikle talaş kaldırma yöntemleriyle temizlenir. Daha sonra, çeliğin işlenmesi için özel kesici takımlar kullanılır.